- Home

- HRSG Inspection

HRSG Inspection

HRSG Inspection

HRST inspectors are engineers practiced in HRSG operation and design. By performing more than 2,400 HRSG inspections since 2008 and now servicing more than 250 annually, we have amassed a remarkable collection of shared experience and know-how. We don’t inform you of a problem―we tell you why it occurs, and then we offer recommendations on action to take, and how to avoid the problem in the future. Each inspection comes with a Final Inspection Report with detailed findings. These findings are sorted by criticality- Click here to find an explanation of HRST’s FMECA criticality matrix. Use the following to request a brochure: HRST Inspections.

Borescope Inspection

Enhanced Access Drone Inspection

This inspection option offers an advanced unmanned aerial vehicle (Drone) technology designed specifically for confined spaces. The advanced drone allows the HRST inspector to more accurately detect and quantify problems by permitting a closer and more stable flight around inspection areas of interest. The drone camera records in high quality video. The advanced drone requires only a a single HRST pilot/inspector stationed either inside or outside the unit. HRST can inspect the higher levels of firing ducts, catalysts, tube faces, and several other hard to reach areas with the help of a drone. Drone inspections offer a cost-effective alternative to scaffolding and allow for frequent upper elevation condition assessments. Results can eliminate uncertainty and be used for informed decision-making and future budgeting.

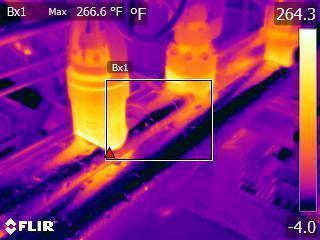

Online Inspection

Steam Drum Weld Inspection Planning and NDE

This inspection option offers onsite drum weld inspection with magnetic particle and/or advanced ultrasonic testing (AUT). HRST will review drawings or past inspection reports to prioritize HP, IP and LP drum welds for inspection. Only ID weld areas will be selected and HRST will prioritize welds to inspect with NDE. Inspection of all welds will not be performed. Which welds get priority will depend on your design arrangement and HRST’s experience with similar drums.

FAC UT Monitoring

In order to draw accurate conclusions about pressure part wear rates due to FAC and form recommended actions, it is important that the components being analyzed are properly measured in the same locations over time. The high priority locations have already been identified by an HRST FAC Risk Assessment. Using this document as a starting point, HRST supplies the client with site-specific Measurement Record Entry Data Sheets (MREDS). Measurements are compared to OEM drawings and any previous testing to determine wear rates and to form predictions of future wall conditions.

Commissioning & Warranty Inspection

We perform inspections before the commercial operation begins (either pre- or post-fire) and during the warranty period following the start of commercial operation. These inspections have resulted in some non-conformance reports and warranty claims to prevent what otherwise would have become future problems and the responsibility of the owner.

HRST Performance Thieves™ Inspection

We offer a speedy inspection where we focus on items that adversely affect thermal efficiency and performance. Based on the results, we may propose additional measures to identify the cost and benefit of potential solutions. That way you can make a sound decision whether or not to recapture MW being lost to Performance Thieves.

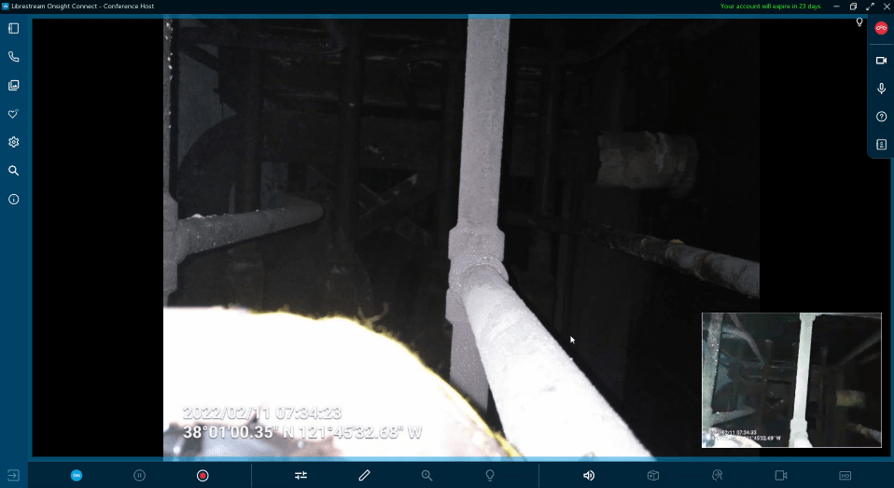

Remote Inspection