- Home

- Products

Products

OUR PRODUCTS

Enhance Efficiency with HRST

HRST engineers, designers and technical advisors inspect and solve many boiler problems during our field service projects. Often the solution is to install a “design upgrade” to avoid future repeat maintenance or problems.

HRST boiler and pressure vessel design and retrofit services are certified by The American Society of Mechanical Engineers (ASME) and The National Board of Boiler and Pressure Vessel Inspectors (NBIC).

Access Doors

Many styles of access doors require two people to open and need frequent repairs to the door frame studs.

Gas Flow Components

HRSGs and power boilers utilize baffling, tube ties, flow distribution grids and vanes to help direct gas flow through the heat transfer.

Liner System Upgrades

HRSGs and many styles of Waste Heat Boilers have an internal Liner & Insulation system to protect the outer casing from the hot exhaust gas.

Pipe Penetration Seals

We can customize all our pipe seals for your specific application. HRST has developed several retrofit pipe penetration seals to replace.

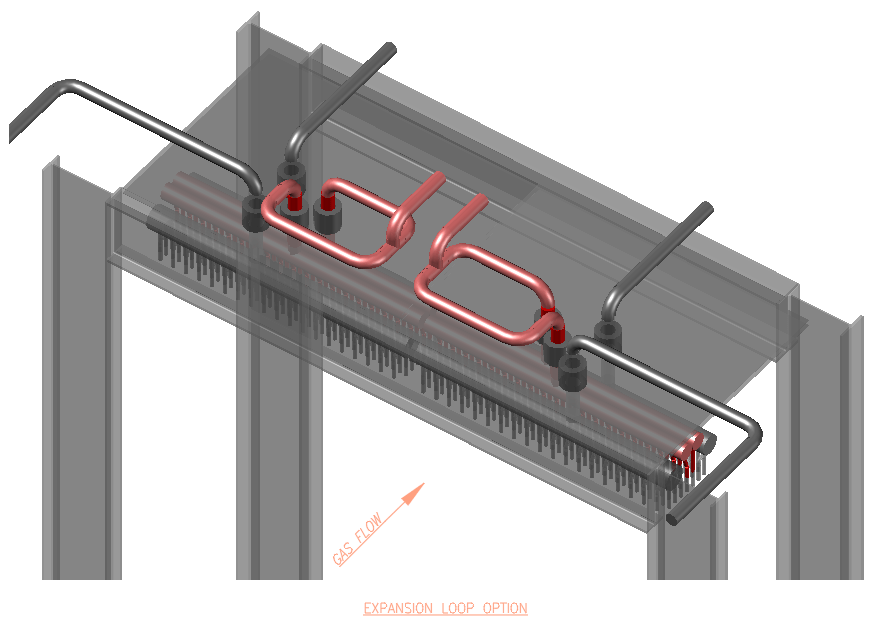

Pressure Parts

Our mechanical design engineering, thermal performance engineering and field retrofit skills can develop the best option and provide performance predictions.

HRST QuenchMaster® Air Attemperation System

Combustion turbine start-up and low-load can damage HRSGs by high exhaust temperature and high attemperator spray water flow.

HRST FlexTune™ HRSG Pressure Control System

Gas turbine (GT) upgrades can lead to excessive steam generation and operating pressure in unfired HRSGs, resulting in the pressure safety valves (PSVs) lifting.

HRST ShockMaster® Economizer

A common problem with HRSG economizers is tube leaks caused by excessive differential temperatures between adjacent tubes.

HRST CoolVision™ Firing Duct Viewport for HRSGs

Overheat and corrosion are common HRSG viewport problems. Additionally window size and internal moving parts can block views of the duct burner flames.